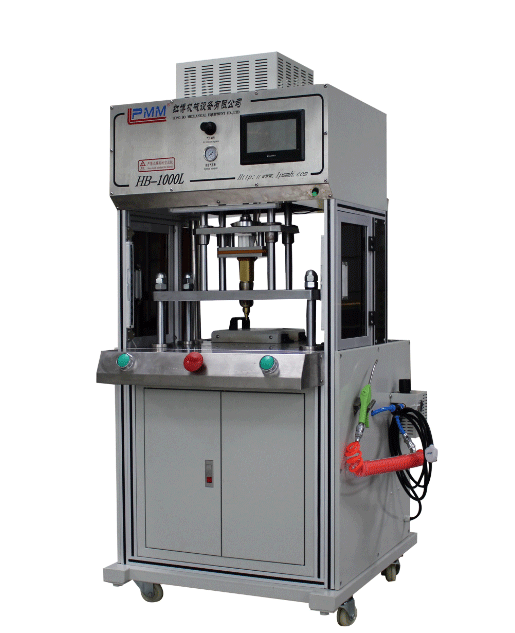

HB - 1000L one-piece top type low pressure injection molding machine

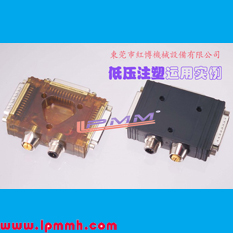

HB - 1000L one-piece top type low pressure injection molding machine 25PIN HD plug

25PIN HD plug HM101 Low-pressure injection plastic material

HM101 Low-pressure injection plastic material Automotive wiring harness mould

Automotive wiring harness mould HB - 900 a C custom side type low pressure injection molding machine

HB - 900 a C custom side type low pressure injection molding machine HB - 1500 rotating disc low pressure injection molding machine

HB - 1500 rotating disc low pressure injection molding machine Lateral low pressure injection molding machine of HB - 2000 double location

Lateral low pressure injection molding machine of HB - 2000 double location HB - 1200 type low pressure injection molding machine

HB - 1200 type low pressure injection molding machine HB - 1000S lateral low pressure injection molding machine

HB - 1000S lateral low pressure injection molding machine  HB - 1000L split type roof type low pressure injection molding machine

HB - 1000L split type roof type low pressure injection molding machine HB - 1000 type low pressure injection molding machine

HB - 1000 type low pressure injection molding machine HB - 800 low pressure injection molding machine

HB - 800 low pressure injection molding machine Cooperation with the customer

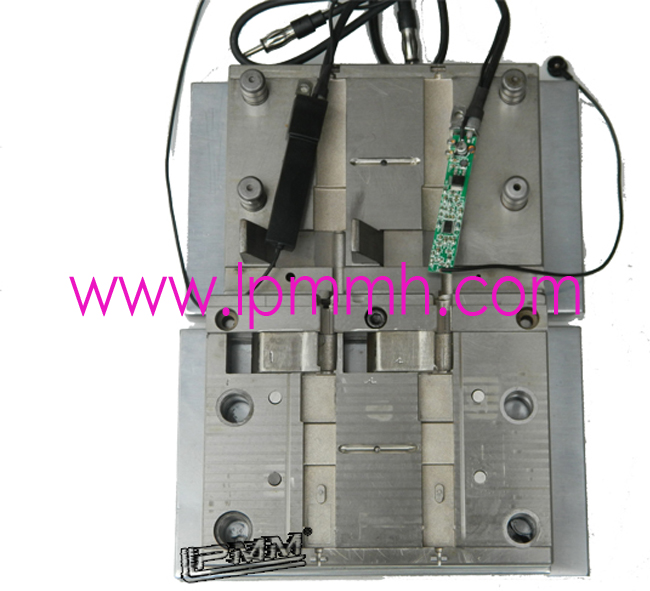

Cooperation with the customer Car battery jig

Car battery jig Car battery jig

Car battery jig

Car battery jig

Car battery jig

4006250270

RedBo Machinery Co Ltd.

Contact:24小时服务电话:13922511557

电话:0769-87980202

Tel:4006250270

Tax:0769-87986585

Emial:联系邮箱:HONG.YANG2008@163.com

Address:The jewel of Dongguan city Tangxia town B Jiao Tang gem Industrial Zone, Road No. 25

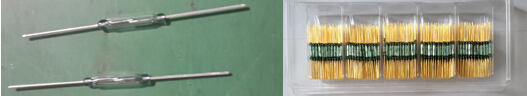

OKI reed imported injection molding and forefoot bending new technology

OKI reed imported injection molding and forefoot bending new technology

Reed (Reed Switch), also known as reed or reed switch, is a special kind of magnetic switch, and is the main component reed relays and proximity switches. Reed working principle is very simple, two endpoints can be magnetized overlapping reed, sealed in a glass tube, the distance separating the two reed only about a few microns, a glass tube filled with high purity inert gases, when not in operation, the spring does not contact two, the applied magnetic field near the end position of the reed piece to produce the two different polarities, the results of two different polarities attract to each other and the closing spring. So technology can be made very small volume of the switch assembly, and the switching speed is very fast, and has a very excellent reliability. Orientation and direction of the permanent magnet is determined when and how many times the switch opens and closes.

Reed is too die package after molding, glass got better protect bent pin can be made after the patch package, further Reel package can be directly due to the structural characteristics of the automatic SMT reed, we cut package when processed using angle curved legs to be especially careful, otherwise, it is likely to cause damage to the reed switch, causing potential quality problems.

All along the lower yield, designed by our own reed package and shear pin bending mold by operating each every three days can be encapsulated bent around 50,000 feet, low pressure injection molding equipment and mold dual turntable mold injection, direct injection after use scissors foot bending mold making products are all curved legs forming. Since for a company supporting the development of complete production lines for the products customers can improve productivity and market share, access to customers.

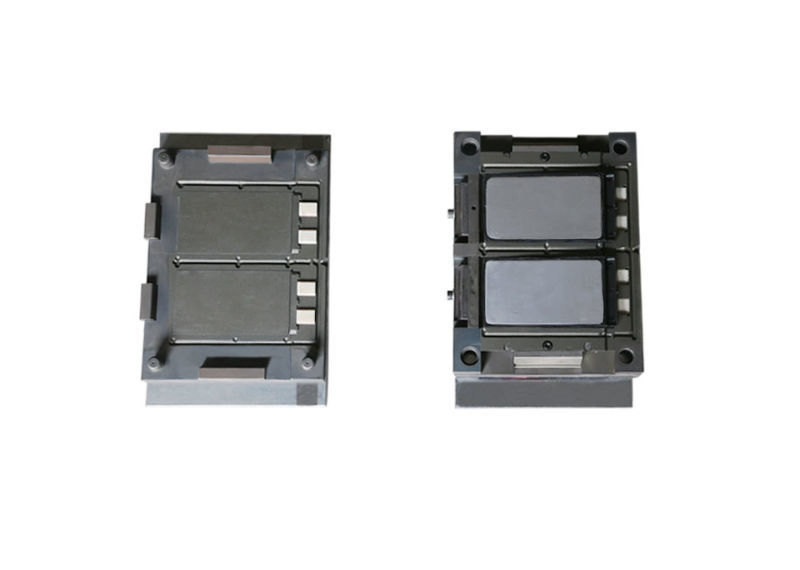

Double injection mold turntable reed

Reed injection molding production line bending and shear pin staffing

News

- Plastic mould industry: only reform just can live

- Amphenol customized equipment was delivered in the United States

- In August 2015, summarizes the general assembly

- HongBo Team have attended Expand training successfully concluded in the TanXia

- Shanghai electronic equipment exhibition in Munich

- Small precision injection mold design principle analysis

- Low-pressure injection molding process is how to apply the LED on it?

- Precision parts machining industry outlook analysis

- Mold surface treatment technology ion and comparison

- Properties of transparent plastic and molding process pay attention to common pr

- Mold making several key points to note

- low pressure injection

- 低压注塑-常见问题解答

- 胶粘剂的发展现状及其前景展望