Current Position: Home>

The enterprise newsThe enterprise news

China's mold industry usher in a new round of development opportunities

China's mold industry usher in a new round of development opportunities

At present, China's mold industry development situation is excellent, while at the technology level, but also an increasing scale of development, it is learned up to now has more than 30,000 enterprises engaged in mold manufacturing, driven by its employment exceeded 100 million, annual gross industrial values approaching 200 billion yuan. But tertiary injection mold manufacturing home tips, our low pressure injection mold industry should be prepared to rely on existing strengths actively pioneering and innovative. With the overall strength of the mold industry, the rising level of the market for customers who require higher and higher mold, fine manufacturing had become the domestic mold industry development trend.

The current development advantage is built on cheap domestic labor and raw material resources, the future along with the disappearance of these advantages, it will bring no small shock to the plastic mold industry. Currently, China's mold industry is still lagging behind manufacturing technology, so even when you catch up with the developed countries to pay more human and material resources, such an action would mean that China's mold industry usher in a new round of development opportunities will also face a huge challenge. So must continue our efforts, because the future development of the road is still long.

Low pressure injection mold

Technologically advanced countries such as Japan, USA, Germany, for the development of high-precision molds and complex nature, whether in design or manufacturing technology capability, has a leading position, but also has a well-trained R & D personnel. Among them, the Japanese mold makers attach more importance to the technical process of polishing and grinding, mold makers from Germany to improve the accuracy and efficiency of the machining and EDM begin to reduce manual processing time. On market size, regardless of the value or decline in domestic demand in Japan is most obvious. On the operating costs, often faced with the problem of high-wage, high welfare, so downstream industries or mold makers gradually moved their production bases near the newly industrialized countries or technical backward countries in order to reduce labor costs, enhance price competitiveness, but this trend often caused by technical virtually outflow concerns, making itself more to be invested large sums of research and development costs, in order to accelerate the upgrading of processing technology and high-speed mechanical properties, widening the difference between them.

"Copyright, reproduced or quoted, please indicate the link and source」

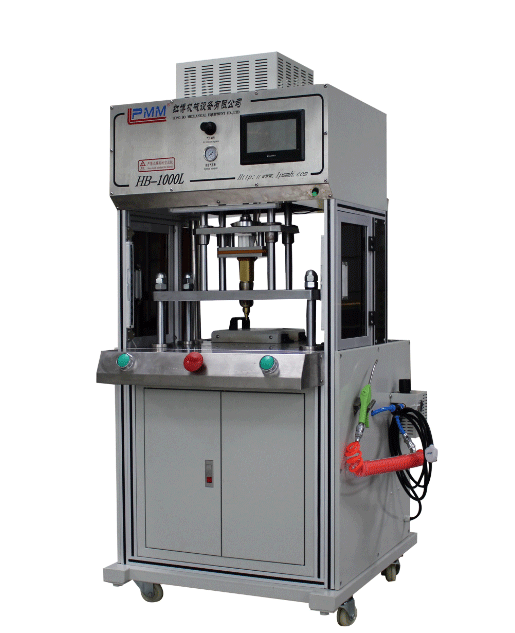

HB - 1000L one-piece top type low pressure injection molding machine

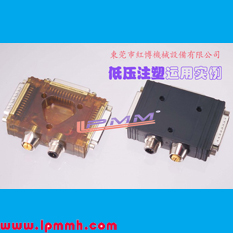

HB - 1000L one-piece top type low pressure injection molding machine 25PIN HD plug

25PIN HD plug HM101 Low-pressure injection plastic material

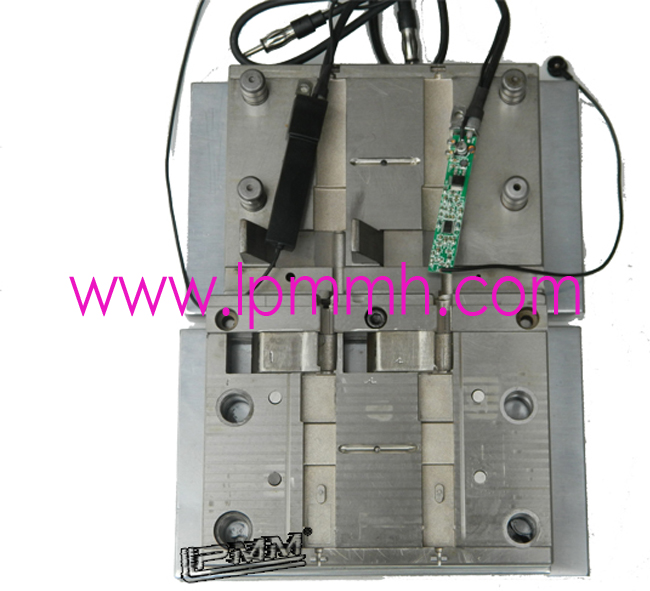

HM101 Low-pressure injection plastic material Automotive wiring harness mould

Automotive wiring harness mould HB - 900 a C custom side type low pressure injection molding machine

HB - 900 a C custom side type low pressure injection molding machine HB - 1500 rotating disc low pressure injection molding machine

HB - 1500 rotating disc low pressure injection molding machine Lateral low pressure injection molding machine of HB - 2000 double location

Lateral low pressure injection molding machine of HB - 2000 double location HB - 1200 type low pressure injection molding machine

HB - 1200 type low pressure injection molding machine HB - 1000S lateral low pressure injection molding machine

HB - 1000S lateral low pressure injection molding machine  HB - 1000L split type roof type low pressure injection molding machine

HB - 1000L split type roof type low pressure injection molding machine HB - 1000 type low pressure injection molding machine

HB - 1000 type low pressure injection molding machine HB - 800 low pressure injection molding machine

HB - 800 low pressure injection molding machine Cooperation with the customer

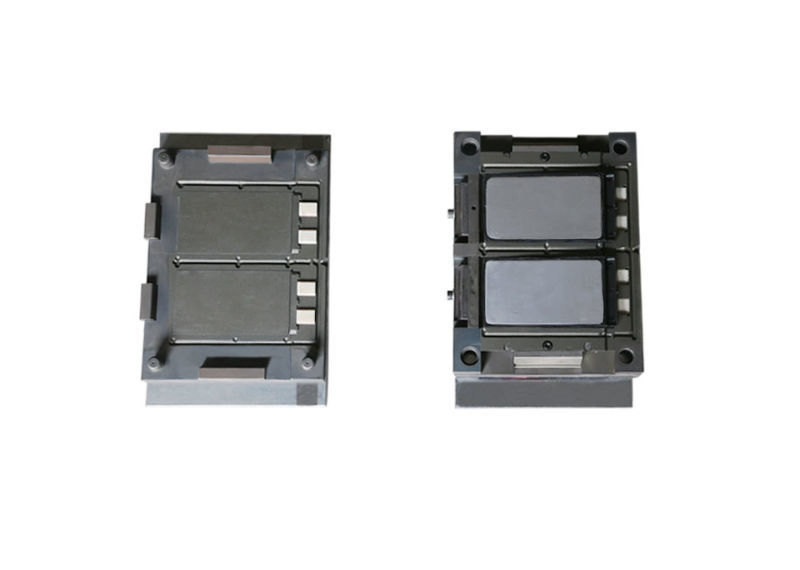

Cooperation with the customer Car battery jig

Car battery jig Car battery jig

Car battery jig

Car battery jig

Car battery jig