|

Service Hotline: 4006250270

|

|

Service Hotline: 4006250270

|

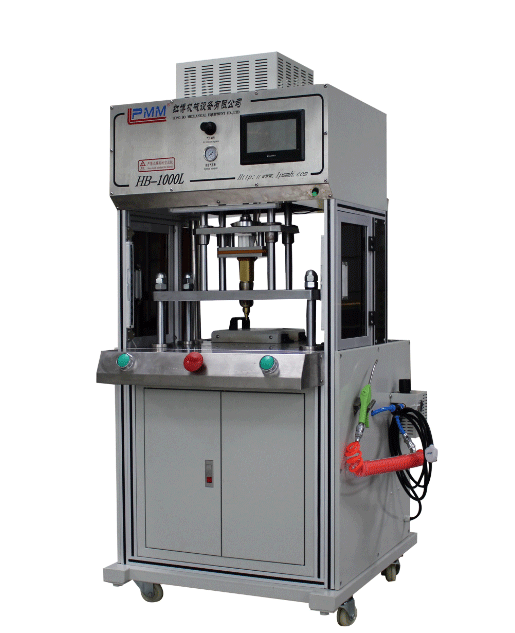

HB - 1000L one-piece top type low pressure injection molding machine

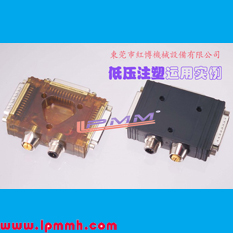

HB - 1000L one-piece top type low pressure injection molding machine 25PIN HD plug

25PIN HD plug HM101 Low-pressure injection plastic material

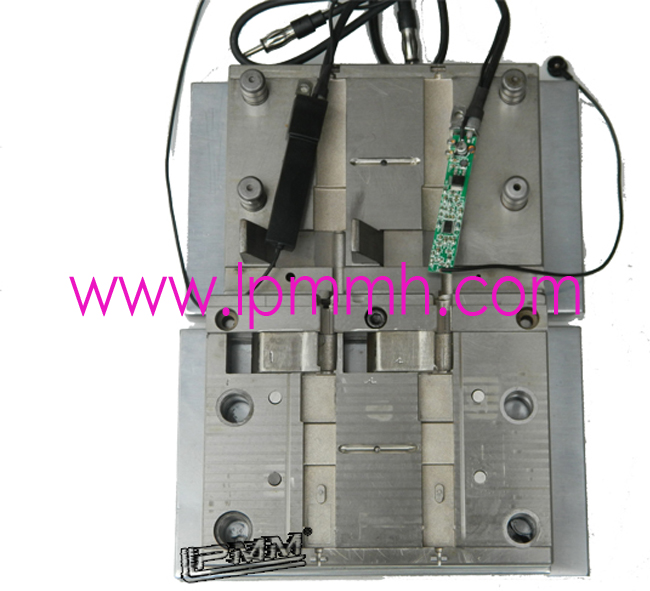

HM101 Low-pressure injection plastic material Automotive wiring harness mould

Automotive wiring harness mould HB - 900 a C custom side type low pressure injection molding machine

HB - 900 a C custom side type low pressure injection molding machine HB - 1500 rotating disc low pressure injection molding machine

HB - 1500 rotating disc low pressure injection molding machine Lateral low pressure injection molding machine of HB - 2000 double location

Lateral low pressure injection molding machine of HB - 2000 double location HB - 1200 type low pressure injection molding machine

HB - 1200 type low pressure injection molding machine HB - 1000S lateral low pressure injection molding machine

HB - 1000S lateral low pressure injection molding machine  HB - 1000L split type roof type low pressure injection molding machine

HB - 1000L split type roof type low pressure injection molding machine HB - 1000 type low pressure injection molding machine

HB - 1000 type low pressure injection molding machine HB - 800 low pressure injection molding machine

HB - 800 low pressure injection molding machine Cooperation with the customer

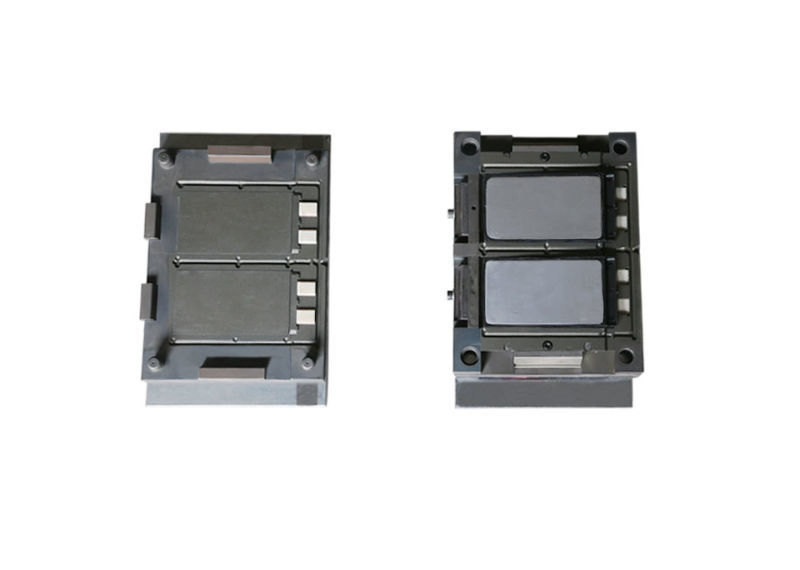

Cooperation with the customer Car battery jig

Car battery jig Car battery jig

Car battery jig

Car battery jig

Car battery jig

4006250270

RedBo Machinery Co Ltd.

Contact:24小时服务电话:13922511557

电话:0769-87980202

Tel:4006250270

Tax:0769-87986585

Emial:联系邮箱:HONG.YANG2008@163.com

Address:The jewel of Dongguan city Tangxia town B Jiao Tang gem Industrial Zone, Road No. 25

一、Some of the users in the development or new product trial production early, oftenonly pay attention to the research and development of products, neglect and mold making unit of communication. Preliminary determination of product designscheme, namely the early contact with the mold manufacturers has two benefits:

(一)、Can guarantee the design product forming process well, not because the material is difficult to machine and modify the design type。

(二)、Mold production can be designed to do ahead of time in a hurry, prevent the ill considered, time. In a word, making high quality die, only the supply and demand sides cooperate closely, to reduce the cost, shorten the cycle of.

二、Don't just look at the price, want to consider from quality, cycle, all-round service:

Many types of mold, can be roughly divided into ten categories. According toparts and materials, physical and chemical properties, mechanical strength,dimensional accuracy, surface finish, life, economy of the different requirements,choose different types of mold forming. Die high precision processing using high precision CNC machine tools, and mold material, forming technology has strict requirements, the need to use the CAD/CAE/CAM technology to design, moldanalysis. Some parts of the molding with special requirements, need to use hot runner mold, gas assisted injection molding. The manufacturer should have CNC,EDM, wire cutting machine tools and CNC profiling milling equipment, high precision grinding machine, high precision coordinate measuring instrument,computer design and related software. The general large-scale stamping die(such as automobile cover mold) to consider whether the machine side pressing mechanism, even the boundary lubricant, multi function progressive etc.. In addition to the punching tonnage consider stroke, feeding device, machine tooland die protection device。

Means for manufacturing the mould and process not every enterprise possess and master. In the choice of cooperation manufacturers must understand theprocessing ability of its, look not only at the hardware equipment, but also with the level of management, processing experience and technical force. For the sameset of mould quotation, sometimes there is a big gap between different manufacturers. You shouldn't have to pay higher than the mold cost at the same time, also should not be less than the cost of mould. Mold manufacturers like you,to obtain a reasonable profit in business. A set of mould can offer much lower will be the trouble began. The user must from its own requirements, comprehensive measure. Die much lower will be the trouble began. The user must from its own requirements, comprehensive measure。

News